Key Features

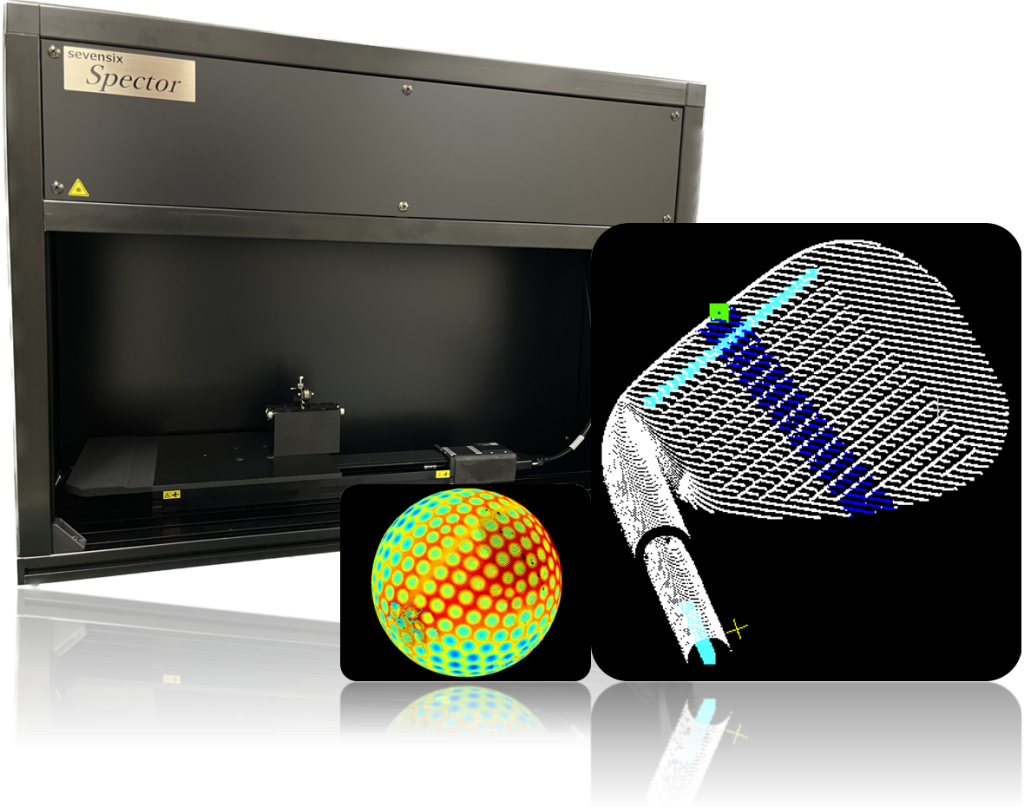

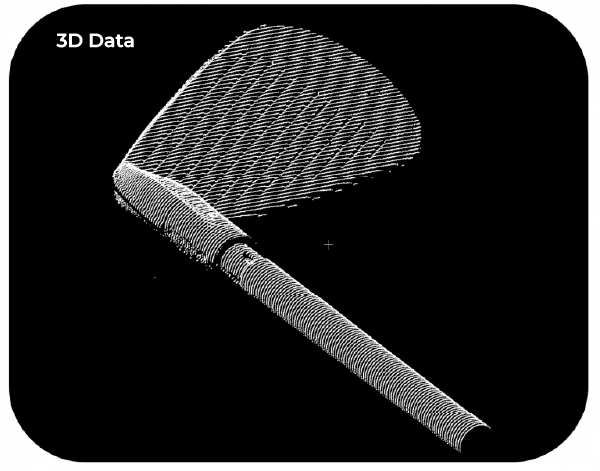

- Non-contact 3D measurement using laser light cutting method x Automatic calculation algorithm

- Golf head with a loft angle of 18°~60° can be easily measured in 4 seconds

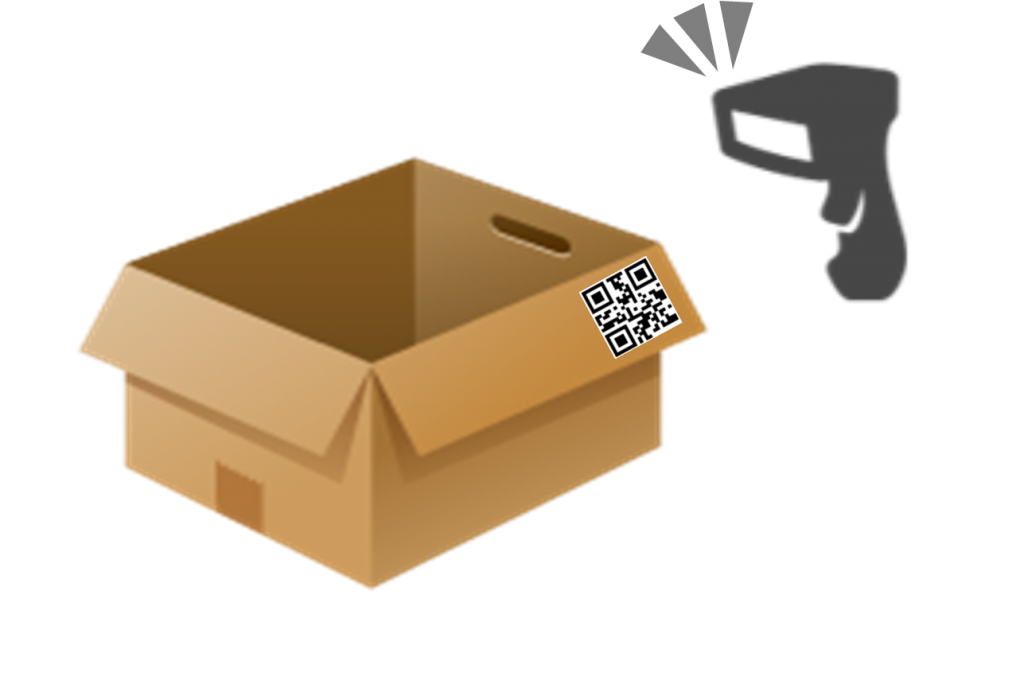

- Traceability is ensured with the QR code reading function

- Left-handed compatible. Measurement is possible with the same settings

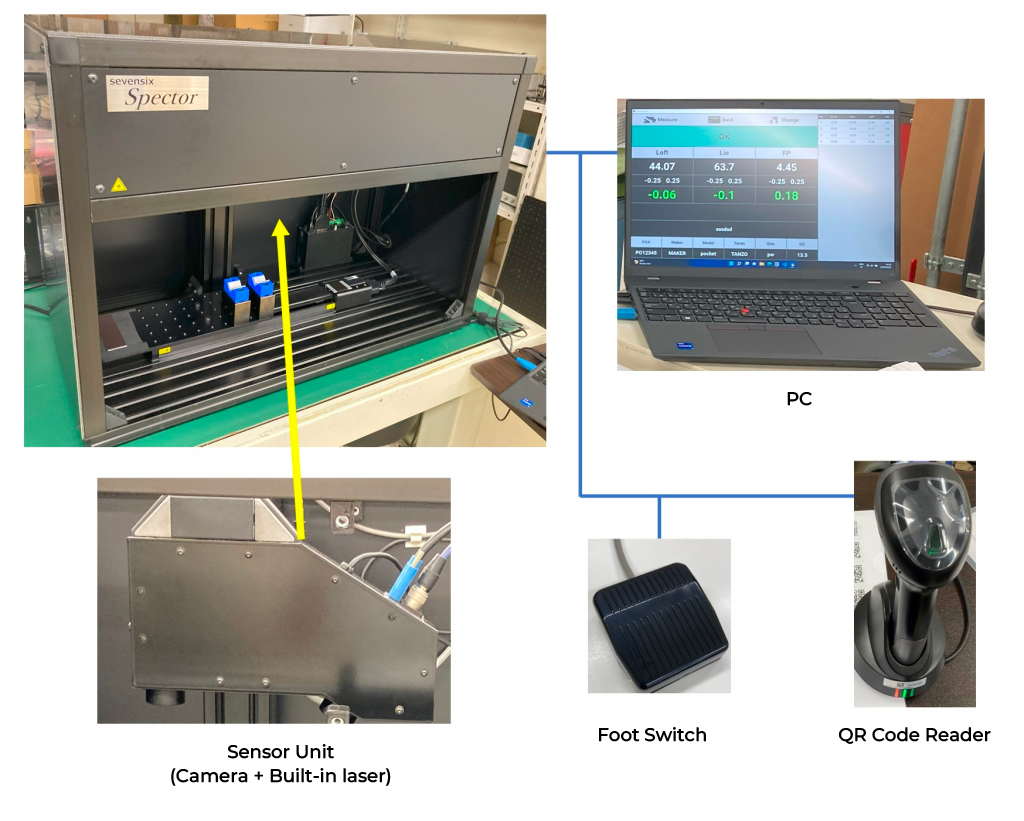

- Dedicated PC & Equipped with various interfaces

Applications

- Golf Head Manufacturing Inspection

- Forging & Casting Inspection (Customized)

- Plating Inspection

>>> Circular shapes such as golf balls can also be measured. Click here for a measurement example

Usage example

In addition to the measurement function, it is equipped with a traceability enhancement function

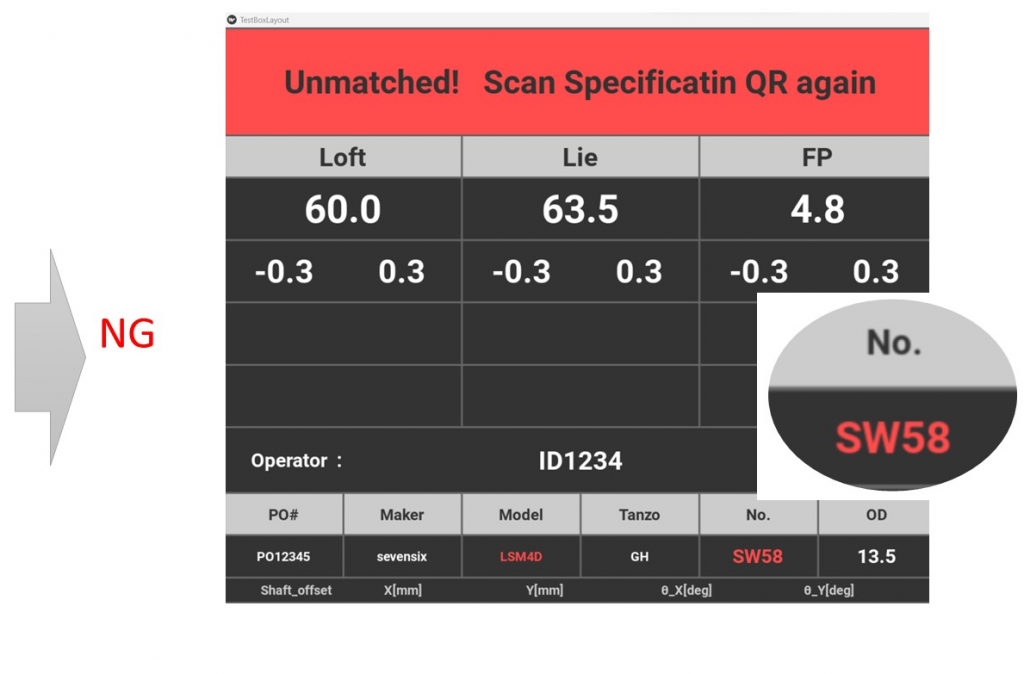

QR code authentication

◆ QR code reader for easy and quick input of inspection data

◆ Matching function to prevent mix-ups

* Barcodes are also supported.

◆ Laser 3D scanning for multi-product measurement

◆ Scanning time of only 2 seconds

[Corresponding surface condition]

Heads with non-mirror surfaces on the face and scoreline grooves (*scorched, matte, and ingots are available)

[Scope of correspondence]

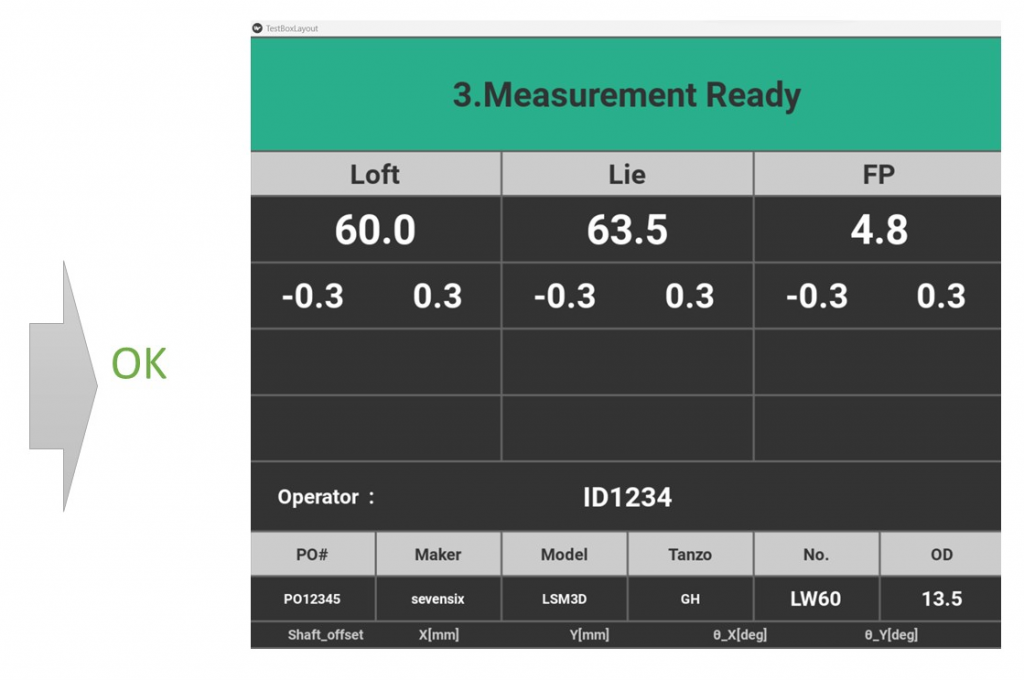

If the loft angle is in the range of 18° ~ 60°, all jigs and settings can be measured with the same jig (*left and right measurement possible)

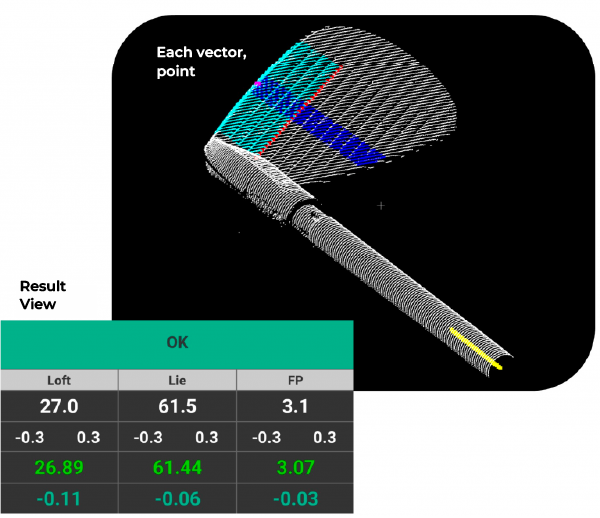

◆ High-speed & high-precision automatic specification calculation program

◆ Determine OK/NG from the difference from the design value

[Calculation algorithm]

Calculate the following from edge detection, fitting, etc., and calculate

the specs

• Shaft vector

• Scoreline vector

• Face surface vector (calculated at ±5mm width from the scoreline center)

• Face spread point (calculated from within the scoreline width, outermost)

▼ Appearance and set contents